-

AuthorPosts

-

-

It’s been a long time since I’ve posted anything on the build for Blucifer, my 2006 Viper coupe. It will have been 4 years this coming Jan since I drove it to 252.588 MPH and a lot of delays between Covid and life in general but hopefully I’m closing in on that next attempt. I’m optimistic that I can get it to the 275 to 285 MPH range with the new build, lots more WHP, torque and so many mods I’ve lost track of them. It’s still not back together but I’ve got some extra help, all the components have arrived, and now it’s just a matter of assembling everything. I will start posting more and sharing pictures of the build as it comes together. Always happy to listen to anyone’s thoughts and suggestions on improvements etc. I’m so looking forward to that view over the hood heading down the runway again.

-

Good to see your update !!

Hopefully, it will all come together…including the weather.

Best of luck to you !!!

-

-

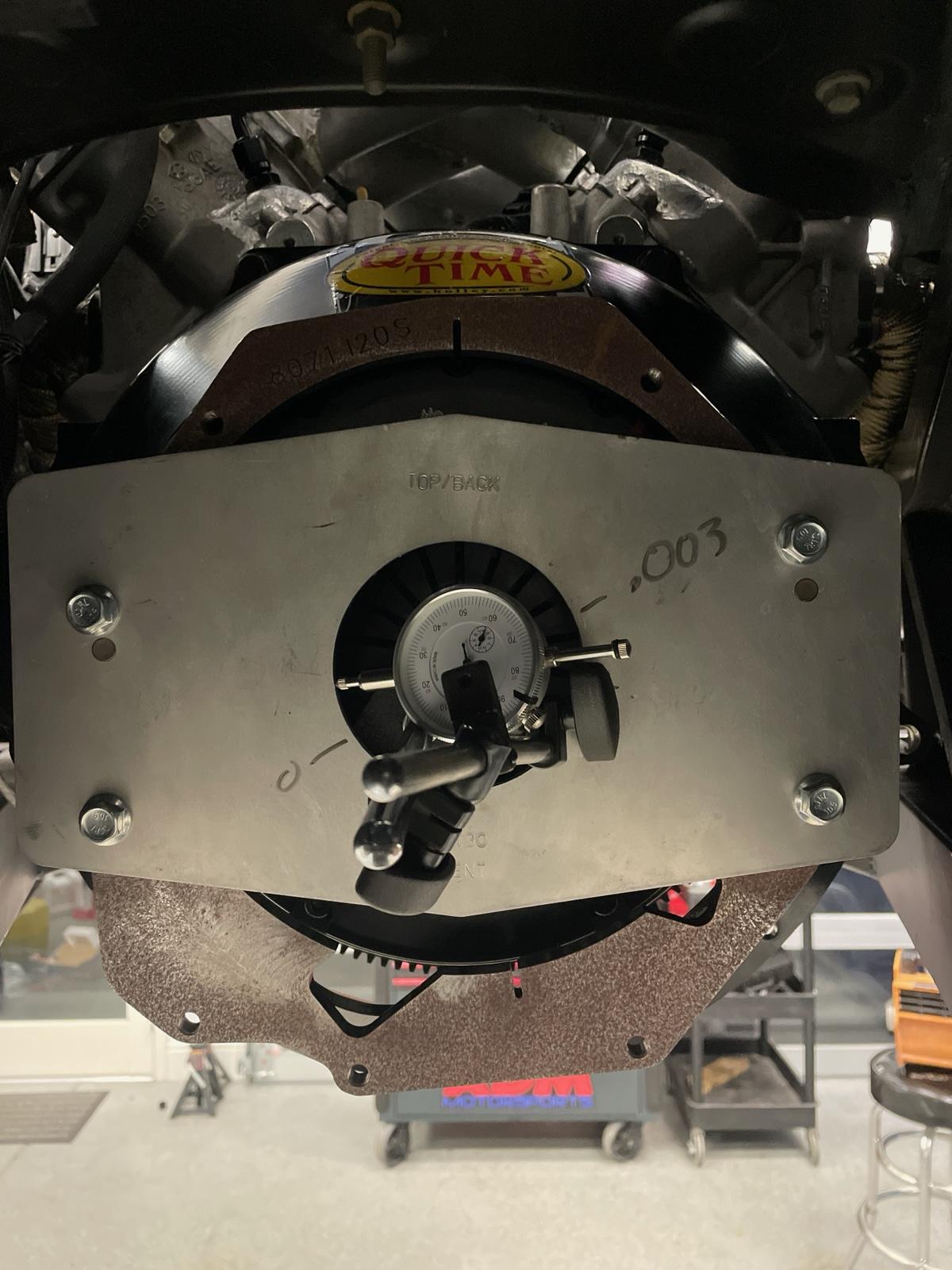

Transmission mount for the 6XD sequential. Gearhead Fabrication in Jenson Beach FL built and installed the mount. Blucifer is now at P1 in Sanford Florida getting the new Nth Moto quad carbon clutch installed along with explosion proof bellhousing indexed. If it all comes together, I want to run in Loring Maine sometime in July. Goal is still something between 275 and 285 MPH. After clutch and bellhousing, it goes back to Gearhead for more fabrication work.

-

I believe I seen this car at a Viper shop just outside of Orlando. Where one of mine sat in pieces for 2 years…..mine is now at Havik Performance in PA and finally back together and running. Actually think I have pictures of Blucifer in pieces next to mine 😂

-

-

-

Hey Brent, yes that’s Blucifer. I just picked it up from P1 in Sanford FL and it’s heading back to Gearhead Fabrication in Jenson Beach. P1 indexed the explosionproof bellhousing and Alex got it to .003 which is an amazing feat. I will be making an attempt at 275+ MPH in the coming months. Really looking forward to driving it and seeing what it will do.

-

-

Man what a small world! I remember the sticker on the windshield of yours and I was like “Holy crap this is the Viper record holder!”. I’m glad you found P1, I’ve heard nothing but awesome things about them. I got tired of waiting for my car to be worked on and in that two years I ended up back up here in Pennsylvania. So I just pulled it out and brought it up here. Havik’s done some crazy stuff with it so far.

Excited to see you go for 275+! You have to post updates!

-

-

Gearhead continues to make progress toward getting Blucifer ready for the next attempt at big speed. Here are a few pictures of the ice boxes, pumps, etc to help keep those IATs in check.

-

-

-

-

Here are some pictures of the cold side connection to the intake. I will run a small nitrous shot to be used if the IATs get beyond a certain number. The plate closest to the intake with the threaded holes is connection point for one side of a “X” brace that clamps intake to the cold side pipes and prevents the hose connection from coming apart as the boost increases on the run. We run boost by gear so every shift bumps that number upwards.

-

-

I’m so looking forward to seeing what it will do at Loring, definitely a base with some history. We will be there for 4 days and will try and post daily results. Thanks, David

-

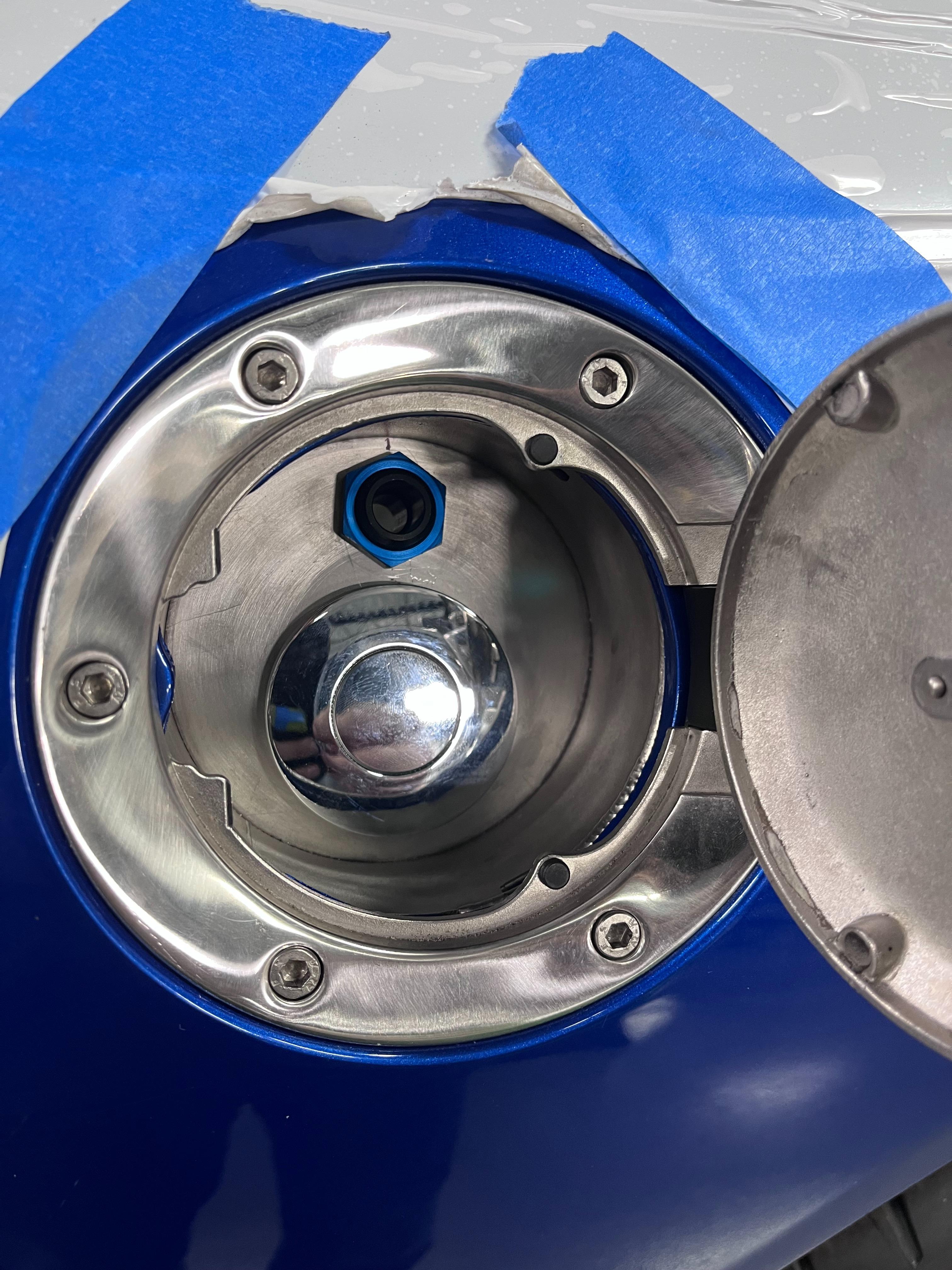

Here are a few pictures of the fuel fill for the Fuelsafe fuel cell. Gearhead Fabrication in Jenson Beach is doing a fantastic job getting Blucifer ready for that 275+ run.

-

This reply was modified 1 year ago by

David Miller.

-

This reply was modified 1 year ago by

-

-

This reply was modified 1 year ago by

David Miller.

-

This reply was modified 1 year ago by

-

-

This reply was modified 1 year ago by

David Miller.

-

This reply was modified 1 year ago by

David Miller.

-

This reply was modified 1 year ago by

-

-

This reply was modified 1 year ago by

David Miller.

-

This reply was modified 1 year ago by

-

Here are some pics of the window net and installation. Blucifer is really coming together and if we can get thru all the assembly and testing I hope to make an attempt at the 275+ number soon.

-

This reply was modified 1 year ago by

David Miller.

-

This reply was modified 1 year ago by

-

Mario at Gearhead Fabrication felt like a harness bar was needed so he added one. Safety is a priority for both Gearhead and me, I never object to spending money on anything that makes Blucifer safer.

-

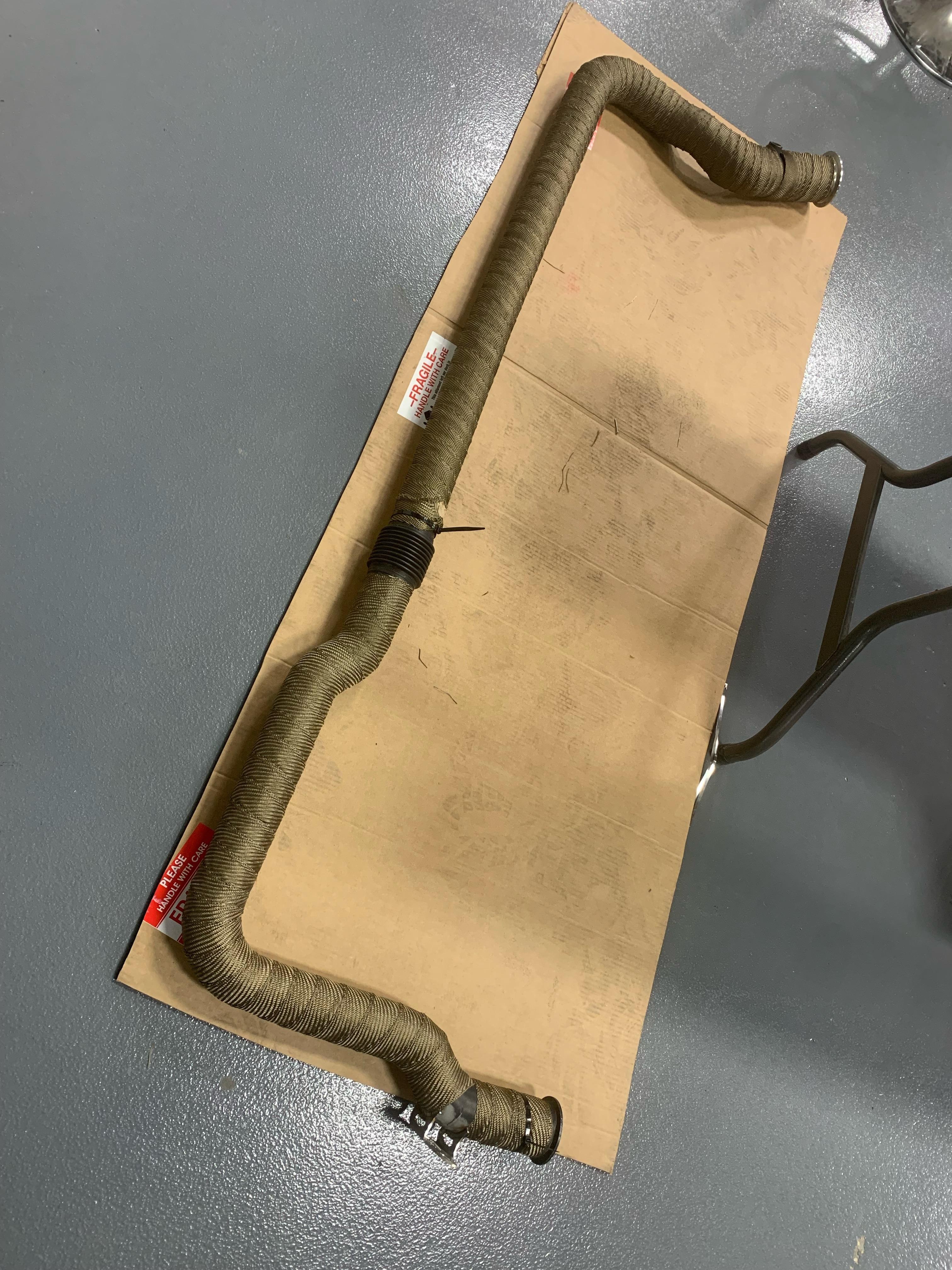

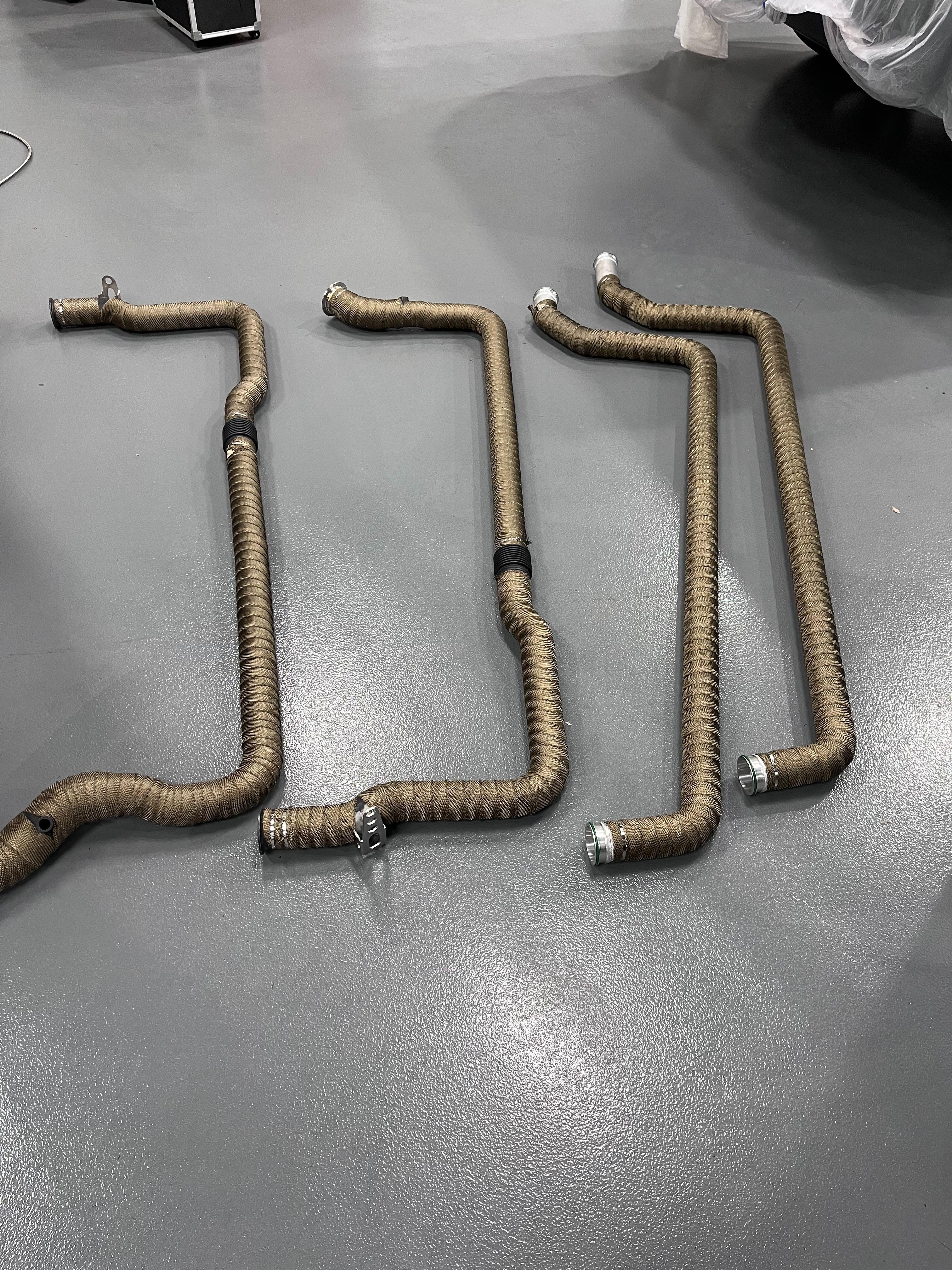

Hot side pipes are both coated and wrapped, hot and cold side both run down the side sills so we are trying to keep them as insulated from each other as possible.

-

Here are a few pics of the rear hatch area. When I first decided that I wanted to put the turbos at the rear I thought I would have so much room to work with, it’s not looking like that now and we are not done yet. Should be an interesting sound from behind thou, I’ve heard a few rear mounted turbos in the past and there is definitely a unique sound to them.

-

Thanks for the updates! Can’t wait to see and hear this thing!

-

Parachute handles are being fabricated; land speed chutes are different than drag chutes in that first chute pulled has the longest tether and smallest diameter chute. It’s designed to straighten out the car and then the 2nd chute is pulled, it’s the deceleration chute, slightly shorter tether and bigger diameter chute is designed to slow the car. Once both are out, I can stand on the brakes and get it slowed down and eventually stopped.

Here are a few pictures of the hot and cold pipes insulated and the valve cover fittings.

-

This reply was modified 1 year ago by

David Miller.

-

David – I just noticed the valve cover photos. These look to be machined from billet? They also appear taller than G3, more like Gen 1/2 with G3 oil filler hole location. What’s the reasoning behind this, other than the “cool factor”?

-

They are billet and definitely taller than the standard G 3, I ran stock Gen 3 before with a spacer for the aftermarket rocker arm clearance. These covers are actually taller than that set up and they do have that cool factor also. I swapped rockers to some from Prefix to ensure we could spin the motor a little more than stock 🙂 I could have probably gone back to the stock covers but I had these and decided why not. Later on I will be doing a lot of painting, powder coating and anodizing of components but I want to make sure everything works first. David

-

-

This reply was modified 1 year ago by

-

Looking at the progress on Monday I’m on the fence as to if we will make it to Maine on time with a car that’s been sorted/tested. There are so many custom “one off” parts in this build that engineering and designing everything to work together is tough. We do expect to start it soon, then if everything is good, no leaks or other issues it’s onto the dyno for the tuning. Even after we are satisfied with the numbers there is a lot of work still to do. All the body panels have to be put back on, aero parts installed, every nut/bolt has to be tightened/checked and so much more. I won’t drive it in Maine unless I have had some seat time in the car. This build is so different than the one I did 252 in that I need time to know how it feels and reacts. We basically have a month and a few days at most to reach that fully assembled and ready to roll if we are going to make Loring Maine, otherwise I will find another option somewhere. I have looked at the ECTA event in Arkansas in early October as a back up but max distance is 2 km or about 1.24 miles, I was hoping for a 1.5 mile run but maybe we go to Arkansas as a test/tune session until I can find a longer runway.

-

Blucifer progress is continuing, and Gearhead is working toward being able to start it soon. Here are some pictures of the catch can which is located in the rear of the car over the battery box. The Peterson oil tank will be vented into it along with the engine. Keeping it in the rear keeps any oil dumped into the tank that overflows out the catch can vent from getting under the tires.

-

This reply was modified 11 months, 3 weeks ago by

David Miller.

-

This reply was modified 11 months, 3 weeks ago by

-

Catch can is completed and ready for all the hose connections. The rear hatch area is getting very busy especially considering we still have more to put back there. At this point our goal is to get it running and then over to a hub dyno for some tuning. I’m hoping that will happen very soon and I will post a video once we reach that point.

-

Here is the catch can installed on top of the battery box and piped thru the floor to be turned out the rear bumper. Still have a lot of hoses and piping to run before we can get it started. I had the Tillett seat pads reworked with new Alcantara and 1/2″ padding. They will be ready next week to install along with the Teamtech harnesses. It’s slowly coming together, and I can’t wait to drive it again.

-

Picked up the Tillett seats on Friday. Had new Alcantara pads put on them with some contrasting blue stitching. Will get them installed soon with the new Teamtech harnesses. Still a lot to do but hopeful we will be starting it soon.

-

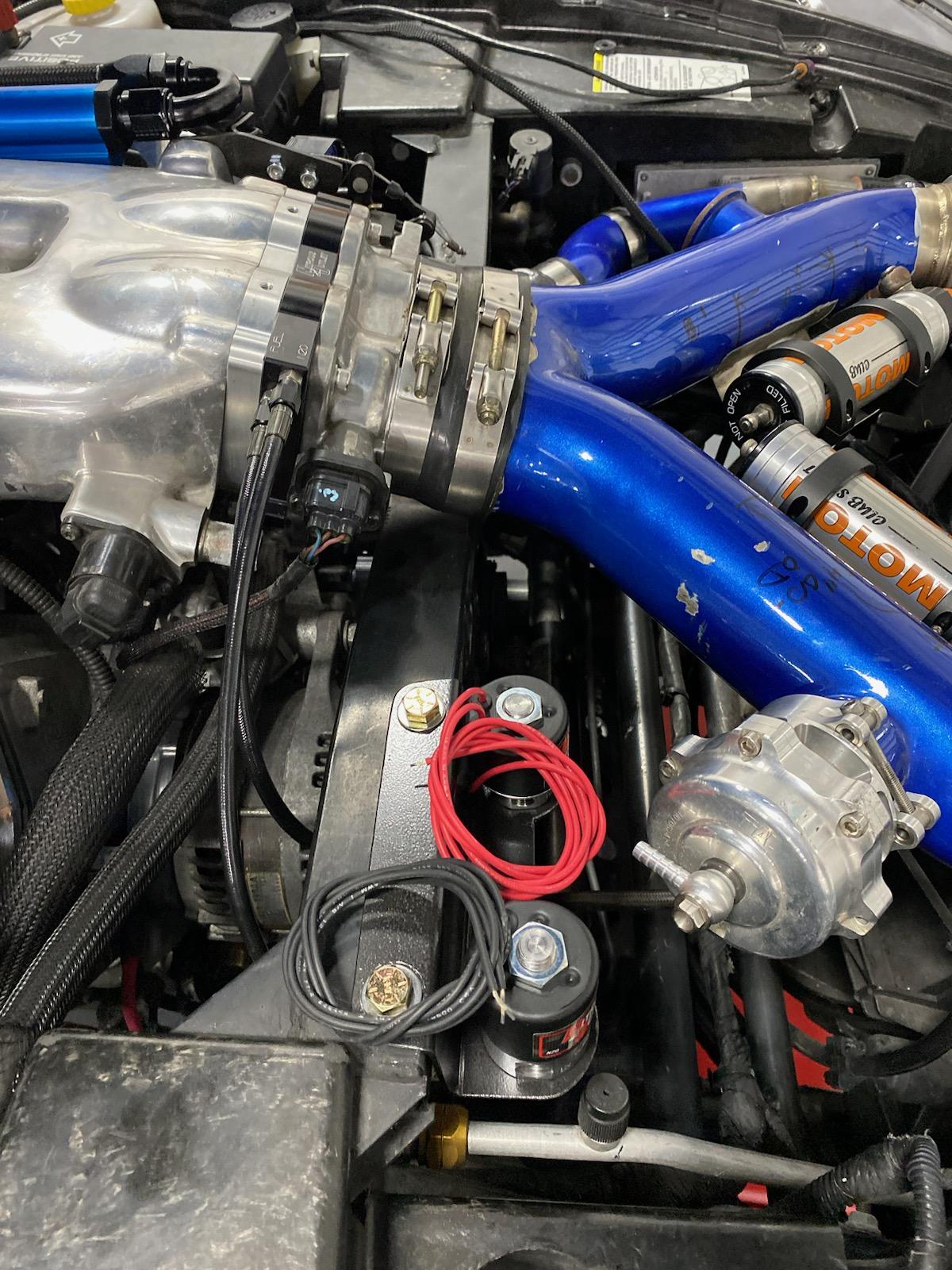

Hoses are all completed, fuel, oil, water, nitrous, scavenge pump, intercoolers and pumps, catch can, etc. Also battery cables and disconnect are completed. ProEFI wants to help us get to 275+ and has helped by sending a base tune and offered to assist with final tune when we are ready. Definitely excited to have the benefit of their experience. All the wiring for pumps and controls are coming up next. This thing is getting close to starting soon.

-

This reply was modified 10 months, 3 weeks ago by

David Miller.

-

This reply was modified 10 months, 3 weeks ago by

-

We are 7 to 9 days away from starting it up. All the lines/hoses are done, nitrous lines, solenoids, purge are completed, battery is connected and disconnect installed. Gearhead will start it up, run it thru a few heat cycles and then shut it down. The following morning the heads will be retorqued, has to be done with the copper head gaskets and fire rings. Then it’s time to put it on the dyno and see what we got. After that there’s a lot of little things that have to be completed before it’s ready to drive but it’s getting there finally!!!

-

Rear hatch area is completely done, all hoses connected, wiring completed, everything bolted in place etc. All fluids were put in earlier this week to include about 7 gals of oil, might be some expensive oil changes in the future. The gas pedal has a toe lift installed, some tech inspections do look for that if you have throttle cables vs fly by wire. We are very close to starting up Dr Frankenstein’s monster and getting it on the dyno. I’m so ready for this moment.

-

Can’t wait to see this thing in action!

-

All the little details on the list are getting crossed off and eventually we will run out of items to do. These pictures that show the plate that keeps cold side pipes, silicone hose and throttle body from coming apart with the big boost I will run. Eventually I will design and machine a clamp block from billet aluminum to make it all pretty for the shows and events but for now this is functionable. The fire suppression nozzles are located at bottom of engine, top of engine, at drivers feet, on the fuel cell and on the turbos/pumps/electrical under the rear of car. There are a combination of automatic nozzles and manual pull nozzles. I don’t like automatic in driver’s cockpit, I want to be able to slow it down before I pull that lever.

-

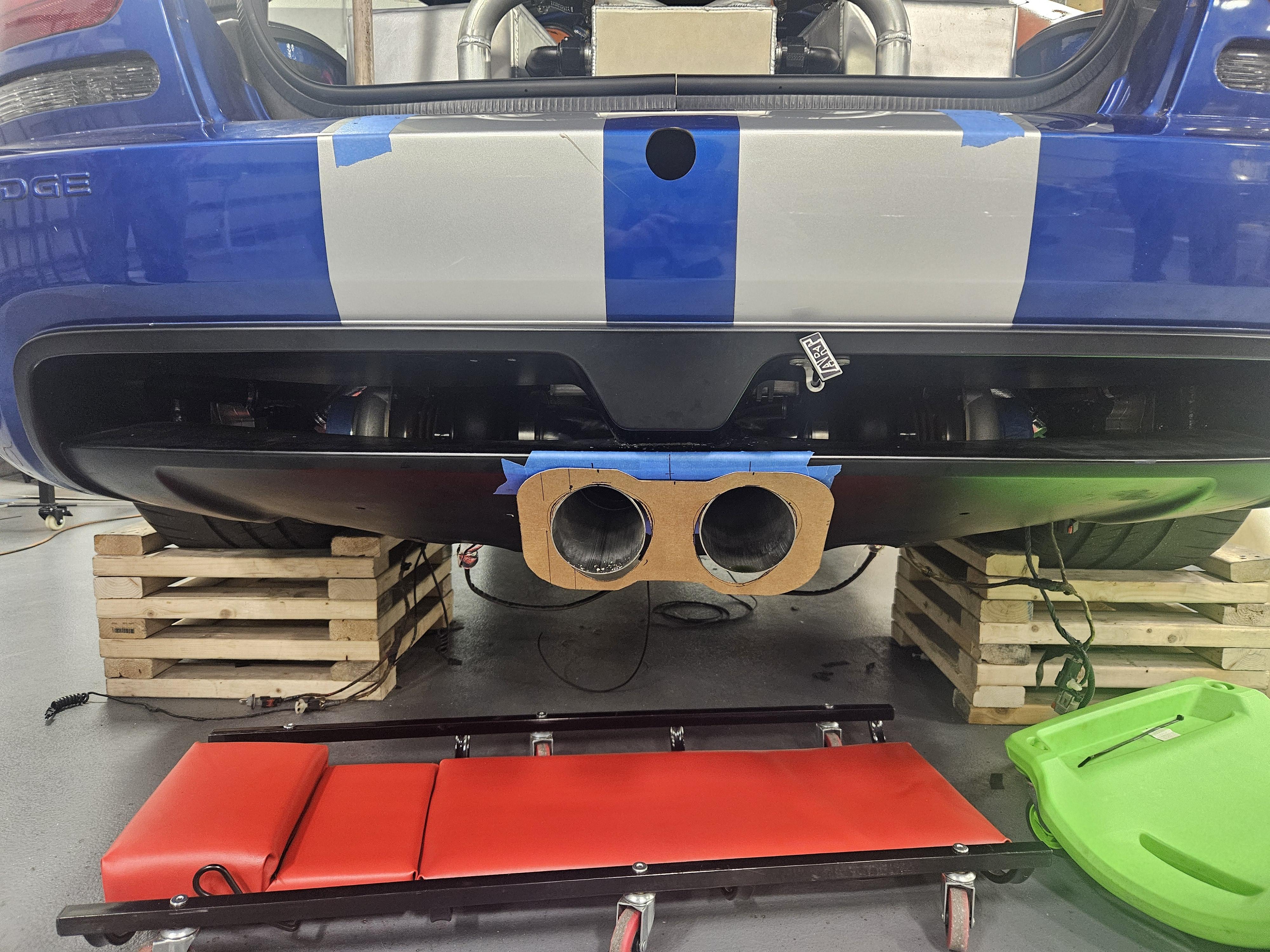

Gearhead is wrapping up the items needed to be done before we start the car. The exhaust pipes will exit the bumper similar to a Gen 2, maybe 2″ pass the bumper. The parachute releases are located, as is the fire suppression pull handles. I went to Gearhead on Thursday and they fitted everything I need to reach with me in the car. Can’t speak enough good about Mario and his guys at Gearhead Fabrication. He has the tune from ProEFI, they stepped up and supplied him with all the help he needed for that. I expect next week Blucifer will be running again. Very excited to hear it, drive it, and so on.

-

Gearhead has tied the wastegate pipes into the exhaust pipes. Makes it a cleaner look vs multiple pipes exited the rear of the car. We had an issue with pushrods being a little too long and holding the valves open. Prefix supplied some shorter lengths and that cleared up the issue. We are down to almost nothing left on the punch list to finish so it’s time……to start it up!!!!

-

Parachute handles are installed in console area. I wanted them close to the shifter, that way I don’t have to take my eyes off the track to just reach over and push levers vs. looking overhead to find them. The levers are mechanically interlocked so that the smaller diameter chute with longer tethers has to be released 1st and then the deceleration chute which is larger diameter with shorter tethers can be released. The 1st chute is designed to straighten out the car if needed. This 2 chute arrangement is new to me so may take me a run or two to get the procedures dialed in.

-

Here are a few pictures of the exhaust as it exits the bumper. The paper template is so we can make a carbon fiber flange that the exhaust will exit thru. On the console we are starting to add the switches for nitrous bottle heaters, etc, keeps them in a good area for me to reach even when harness is tight.

-

Here are a few pictures of the NACA ducts that will help to feed air to the rear mounted turbos. The ducts will not be connected directly to the turbos but just help to put additional air in the right area for the turbos to make use of. The turbos have very large filters so there isn’t any concern about any dirt picked up by the NACA ducts being located behind the rear wheels.

-

The new Motec M150 is installed along with Boomslang harness. Gearhead has built multiple other harnesses for the sequential, all the pumps, etc, very professional with color coded and numbered along with complete set of schematics in case we need to track something down in the future. On top of all that the best news is Blucifer started up yesterday and idled. Dyno won’t be much longer at this point.

-

Here is a link to the start up video for Blucifer.

-

Here is a pic of the dash plate wrapped in flat black, this is where we will locate our sponsor decals, so they are visible in the videos. The passenger seat has been installed if anyone wants to volunteer to ride along :). Gearhead also added a second spring as tech inspection requires this on throttle bodies that are not drive by wire. Dyno should be next week, Gearhead has everything pinned on the MoTec so it’s pretty much ready for that final tune.

-

Blucifer is on the dyno and should be tuned soon. Had some issues with battery kill switch but that’s resolved now. Been looking forward to this for a really long time.

-

David Miller

GuestApril 3, 2025 at 1:26 amPost count: 9https://youtube.com/shorts/9r88nOMvRAw?si=5rYy8ls24n0YNP1J

Here is a video from Saturday March 29th at Celebration Exotic Car Show.

-

-

AuthorPosts

- You must be logged in to reply to this topic.